AIRCRAFT DUCTING

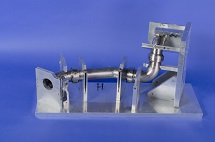

As a market leader in the design and manufacture of engineered metallic ducting assemblies, RSA’s products can be found in the most critical applications of the aircraft. Ducting assemblies are custom-engineered to our customer’s performance requirements to ensure robust, reliable ducting designed to last the life of the aircraft.

RSA’s ducting products are commonly found in critical close-toleranced systems throughout the aircraft including:

- Engine Bleed (EBU)

- Thermal anti-ice (TAI) such as piccolo tubes

- Pylon ducting

- Fuselage

- Inlet / Exhaust

- Environmental Control Systems (ECS)

With over 50 years of high-pressure/high-temperature ducting design experience, RSA is a trusted supplier to the world’s largest commercial and military airframers and their Tier 1 integrators.

With NADCAP approved welding at the core of our business, RSA provides complex welded ducting assemblies made from Stainless Steel, Inconel, Titanium and Aluminum. RSA is well versed working with diameters from 1″ to 17″ and above, in both conventional round cross sections as well as out-of-round and formed details.

As a manufacturer of flexible pneumatic joints such as bellows ball joints and gimbal joints, RSA can engineer flexibility into your ducting run to accommodate aircraft movement and thermal expansion effects.

RSA also provides the capability to design and manufacture insulation in-house with both lower-duty elastomeric blankets as well as high-performance polymide shells. Given a set of temperature requirements, RSA can design an insulation system optimized for both performance and cost.